Derby Car

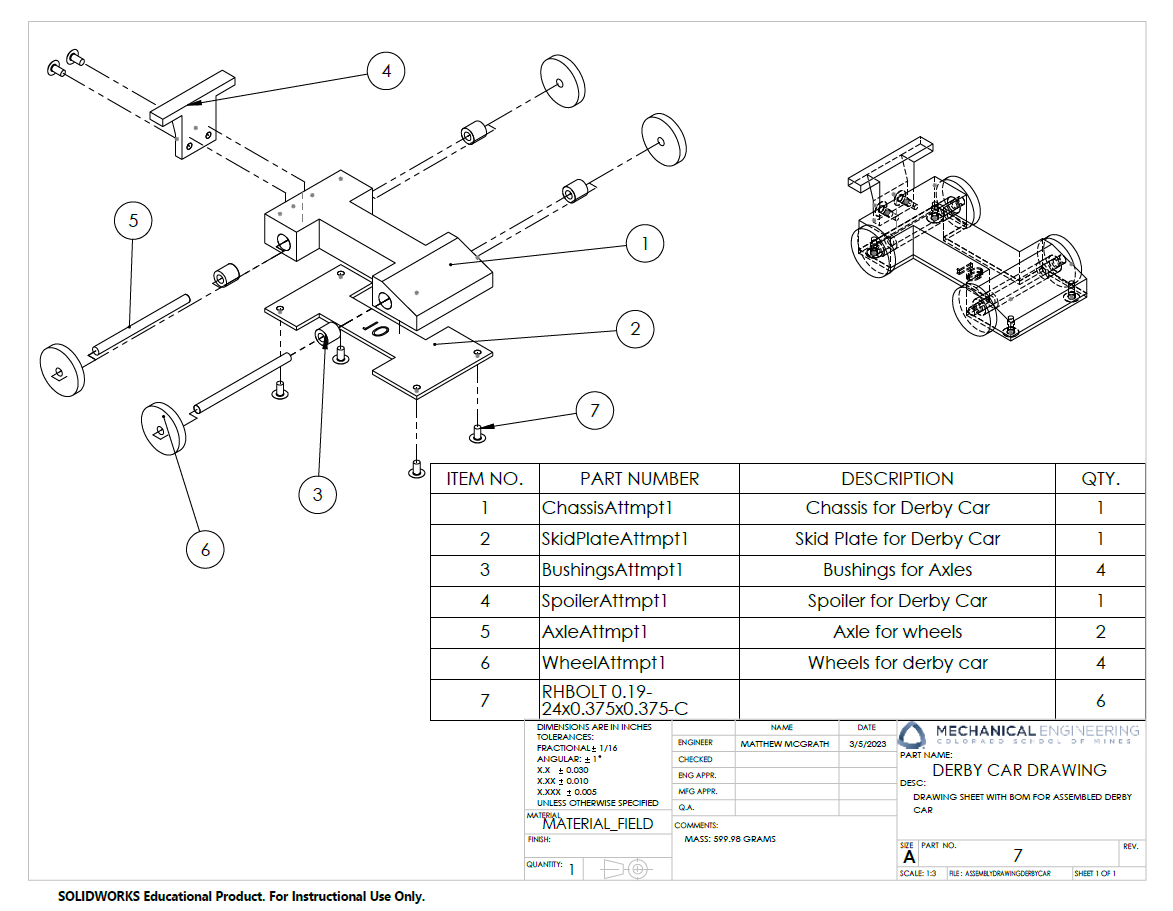

This project is my final project for MEGN201 (Introduction to Mechanical Engineering: Design & Fabrication). This was a group project that I did with two other people. Together, we had to design and fabricate a derby car.

Requirements

- Between 3 and 5 inches wide (in order to fit on the track)

- No more than 6.25 inches long

- Between 250 and 650 grams

- Axle bushings that press fit into the chassis

- A spoiler that protrudes at least 1 inch above the top of the car

- An acrylic skid plate on the bottom of the car

- Must only use given materials (no adhesives or lubricants)

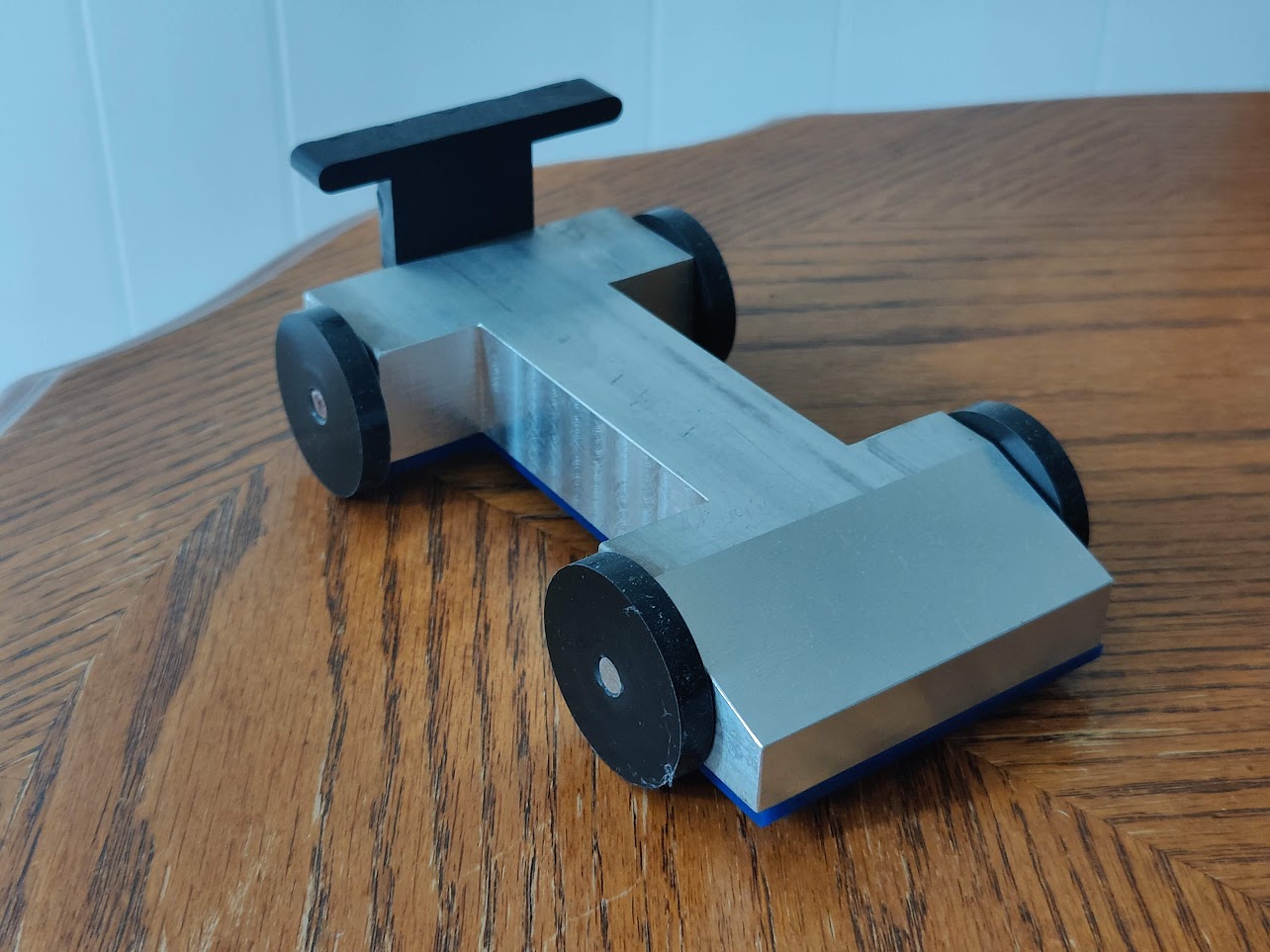

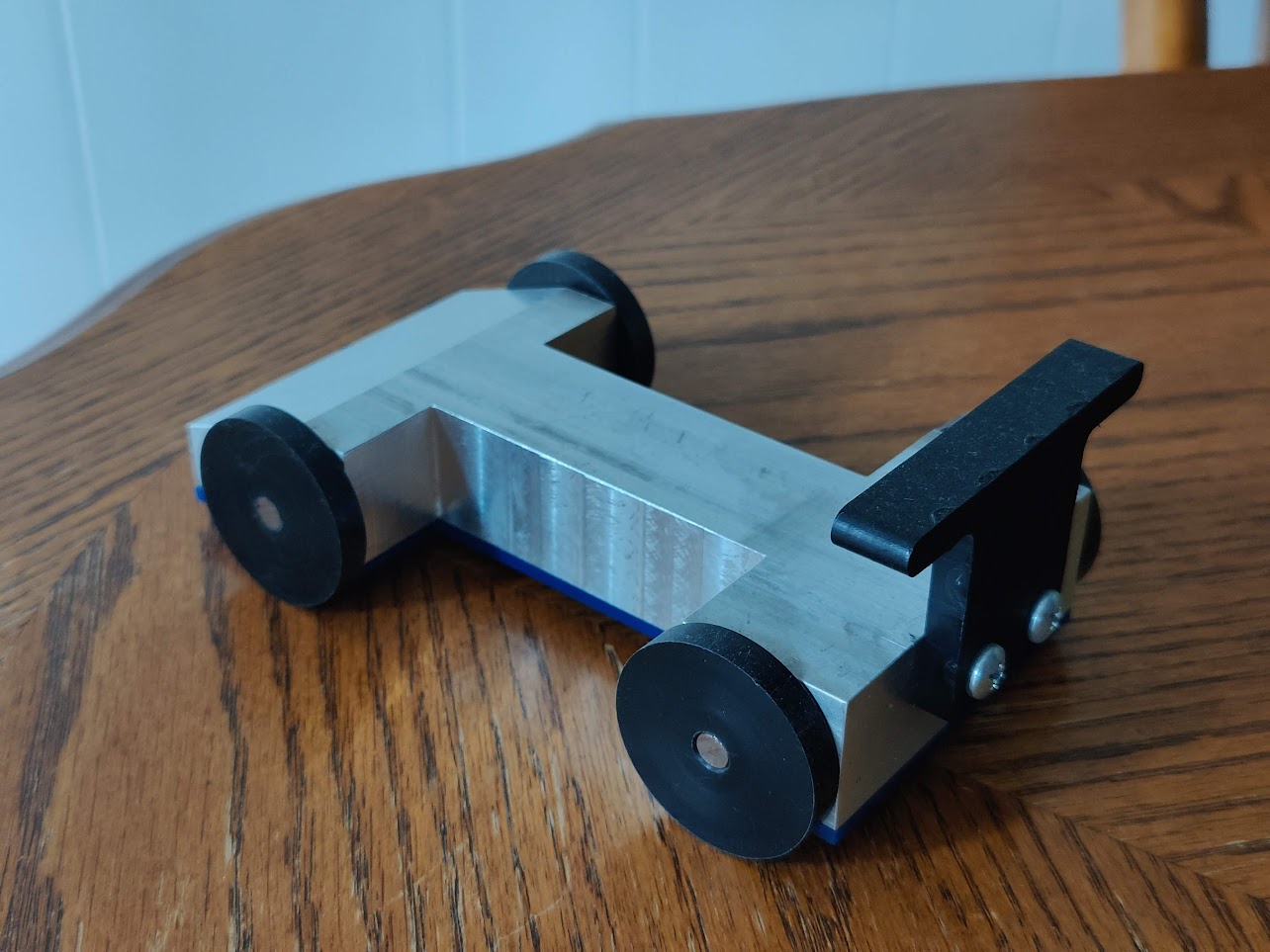

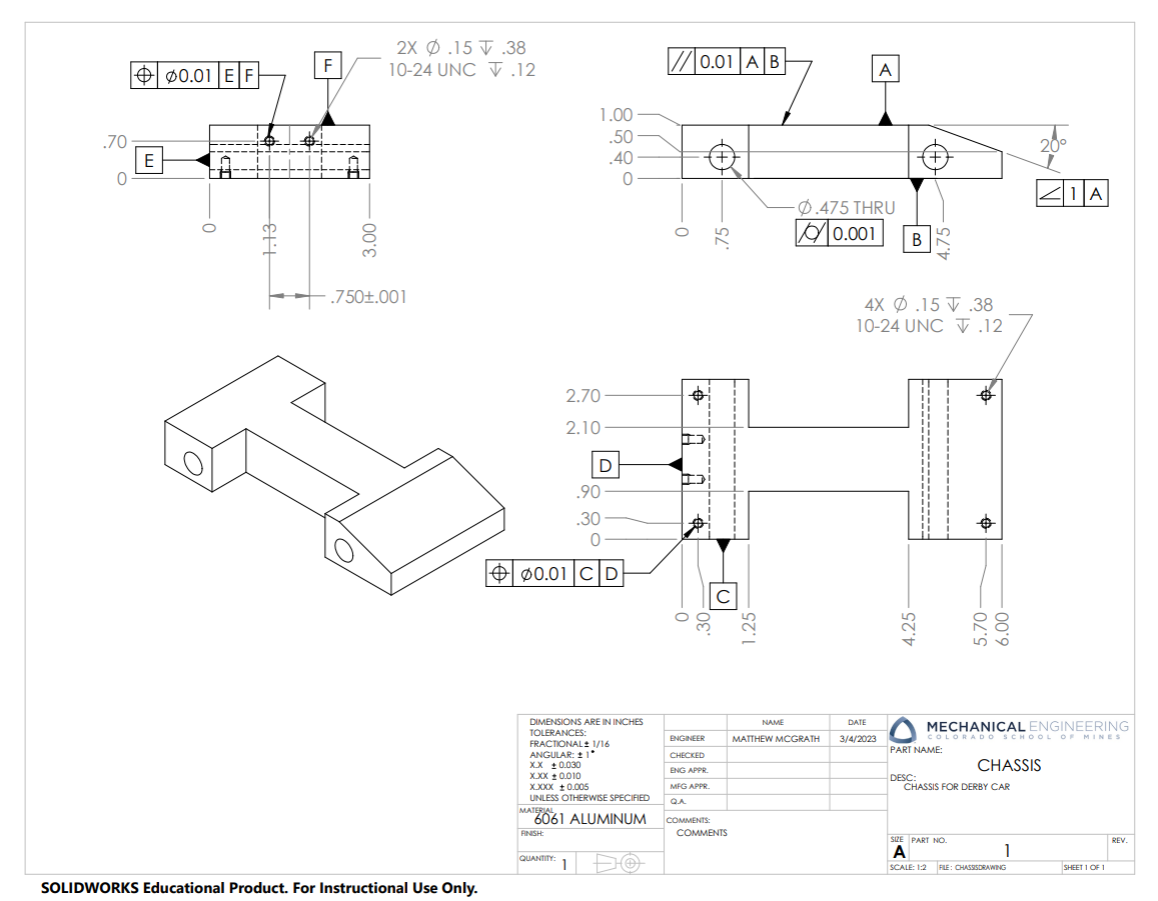

Design

The design we settled on was an I-beam style design with a small slope on the front. We chose this design for its ease of manufacture. We also included the large cut outs to save weight.

Construction

The chassis was machined from a block of 6061-T6 aluminum. This was done using a Bridgeport milling machine. The skid plate was cut from a sheet of acryclic using a laser cutter. The bushings were machined from a rod of nylon using a lathe. This was easily the most challenging part to machine, due to the flexibility of the nylon stock. This made it tricky to machine the outer diameter of the bushings to the appropriate size to create an interference fit in the chassis of the car. The spoiler was cut from a block of delrin using a Haas desktop CNC milling machine. We had to create the toolpaths for this operation using Inventor CAM. The axle was the easiest part. It was simply cut to length from a rod of steel using the bandsaw. The wheels were turned on the lathe from delrin round stock.

The Race

On the day of the race, four cars were placed on a sloped track and released at the same time. The two events were speed and distance. Our car managed to take second in the speed event, but the car did not

run straight enough to place in the distance event. Overall, our car was very successful because it did not fall apart during the race.